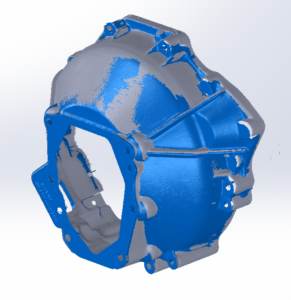

Lase r scanning of products is an efficient and time saving way of defining a product. Manual measuring and updates can be extremely expensive alternative. 3D laser scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light. The output of Laser Scanning is a point cloud of data and this point cloud can be converted to an editable 3D model.

r scanning of products is an efficient and time saving way of defining a product. Manual measuring and updates can be extremely expensive alternative. 3D laser scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light. The output of Laser Scanning is a point cloud of data and this point cloud can be converted to an editable 3D model.

Benefits of Laser Scanning

- Some of today’s legacy products only have 2D drawings and physical models and Laser Scanning can be used to develop a new 3D model

- Reverse engineering can be much easier when using Laser Scanning to define complex geometry

- The “as built” condition of some products can vary greatly from the initial design and Laser Scanning can be a great tool to document the revision

- Easily deisng part to fit up with an existing part

- Can be accurate for very fine details

- An inexpensive way to inspect complex parts

Applications for 3D Laser Scanning

- Reverse engineering

- Inspection and metrology

- Large object scanning

- On-site facility layout confirmation