In the manufacturing of new products, we are concerned with using a quantitative approach to optimize how a process, system or organization operates. Our team has worked on industrial engineering projects with some of the best companies in the world including Honda, BMW, Chrysler, Little Tikes, DuPont, and many others.

Our capabilities include:

- Standard Work

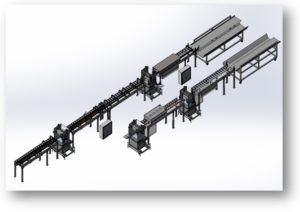

- Work Cell Layout – 2D and 3D

- Assembly Line Layout – 2D and 3D

- Factory Layout – 2D and 3D

- Setup Reduction (SMED)

- Operator Instructions

- Material Control (Kanban)

- Total Productive Maintenance (TPM)

- Value Stream Mapping

- Facilities Planning

- Factory Simulation

- Continuous Improvement Activities (Kaizen)