Here at NLS, our material engineering teams are reducing material in new products by using digital prototyping tools to evaluate design options and validating the robustness of the design with structural analysis tools (FEA) as we work to make them lighter. We are using several strategies to improve part design including adding reinforcements, reducing force and stress concentrators, and putting parts into tension where applicable.

There is a tremendous environmental push in markets to reduce the resources we are consuming through the life cycle of new products. Surprisingly, it takes seven pounds of materials to make one pound of steel, and 85 pounds of material is required to make one pound of aluminum. Even small changes in products can have tremendous effects on their environmental footprint. Products with less material have less negative impact from production to disposal and are often cheaper to produce.

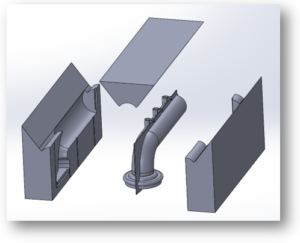

We add reinforcements such as hollow sections and thinner walls, local reinforcements, posts and ribs, and trusses ahnd gussets. Once changes are incorporated into the design, digital prototypes–which are an essential tool in lightweighting parts–are used to test the new designs against strength and stiffness requirements.

The beauty of digital prototyping is that many different alternatives can be tested and the design substantially improved without using costly and time consuming physical prototypes. Dynamic digital prototypes can also be created where we can calculate the forces that act on a design as it moves and operates.